Simulation

Selected publications

M. Faden, A. König-Haagen, S. Höhlein, D. Brüggemann:

An implicit algorithm for melting and settling of phase change material inside macrocapsules.

International Journal of Heat and Mass Transfer, vol. 117, pp. 757-767, doi:10.1016/j.ijheatmasstransfer.2017.10.033 , February 2018

A. König-Haagen, E. Franquet, E. Pernot, D. Brüggemann:

A comprehensive benchmark of fixed-grid methods for the modeling of melting.

International Journal of Thermal Sciences, vol. 118, pp. 69-103, doi:10.1016/j.ijthermalsci.2017.04.008 , August 2017

R.R. Kasibhatla, A. König-Haagen, F. Rösler, D. Brüggemann:

Numerical modelling of melting and settling of an encapsulated PCM using variable viscosity.

Heat and Mass Transfer, pp. 1-10, doi:10.1007/s00231-016-1932-0 , Springer-Verlag, Berlin Heidelberg, Oktober 2016

P. Klonowicz, F. Heberle, M. Preißinger, D. Brüggemann:

Significance of loss correlations in performance prediction of small scale, highly loaded turbine stages working in Organic Rankine Cycles.

Energy, vol. 72, pp. 322-330, doi:10.1016/j.energy.2014.05.040 , August 2014

I. Milcheva, F. Heberle, D. Brüggemann:

Modeling and simulation of a shell-and-tube heat exchanger for Organic Rankine Cycle systems with double-segmental baffles by adapting the Bell-Delaware method.

Applied Thermal Engineering, vol. 126, pp. 507-517, doi:10.1016/j.applthermaleng.2017.07.020 , November 2017

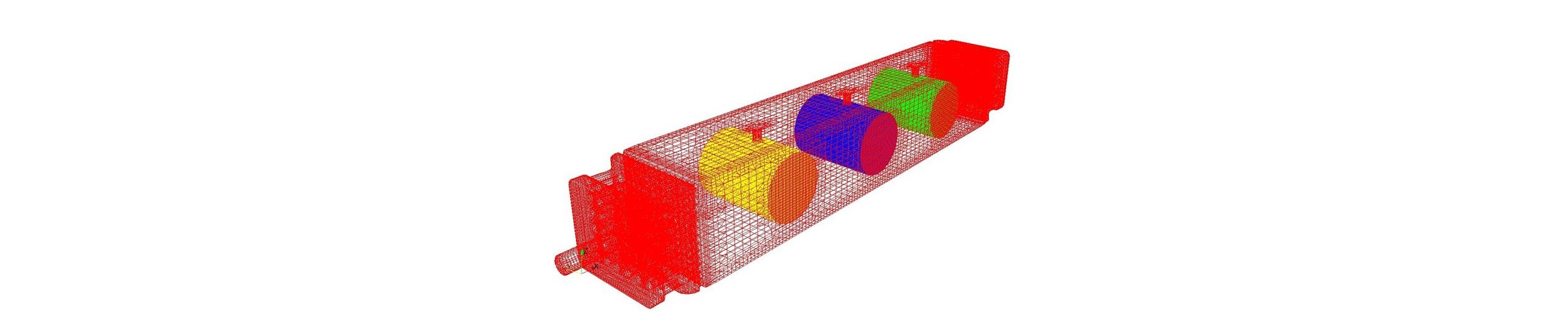

With the help of numerical simulation, the analysis and optimization of processes including thermofluiddynamic phenomena can often be carried out more efficiently than by experiments alone. Therefore, in order to better understand and optimize these processes, the LTTT makes use of thermofluiddynamic simulations in almost all research fields. To ensure accurate and reliable results, special attention is always paid to the validation of the models applied. The validation is achieved by comparing the numerical results with comparative experiments. In selected areas such as the simulation of solid/liquid phase change - the development and optimization of thermodynamic simulation models is in the foreground in addition to the application. Selected examples in which the thermofluiddynamic simulation at the LTTT plays a major role are:

- solid/liquid phase change in latent thermal energy storage

- Analysis and optimization of heat exchangers

- Spray and partice propagation in combustion processes

- Cooling of current-carryingcomponents

Contact person: Dr.-Ing. Andreas Obermeier